Physical Proof of Work

My recent detour into graphic and fashion design and observing the similarities to writing code.

There's nothing more satisfying than seeing your virtual work come to life as a physical product.

Virtual work is something I've been struggling with all year. I'm not like many folks who are full time in Nostr and Lightning development, I do what I can to try and squeeze things in on the side, late nights and weekends. Some days I'm not even sure what I do even matters. Its a depressing thought but often content is created and then just forgotten.

That's why I decided to make some designs and have a go at something tangible.

The Simple T-Shirt

The cool part about testing and making designs these days for stock items like t-shirts and hoodies is that its become fairly simple with existing online design tools and print on demand.

So lets start where everyone begins, making a custom designed T-shirt. This is a fairly easy task, find a picture or graphic and center it on a digital t-shirt mock-up. Done!

Complex 2D → 3D designs

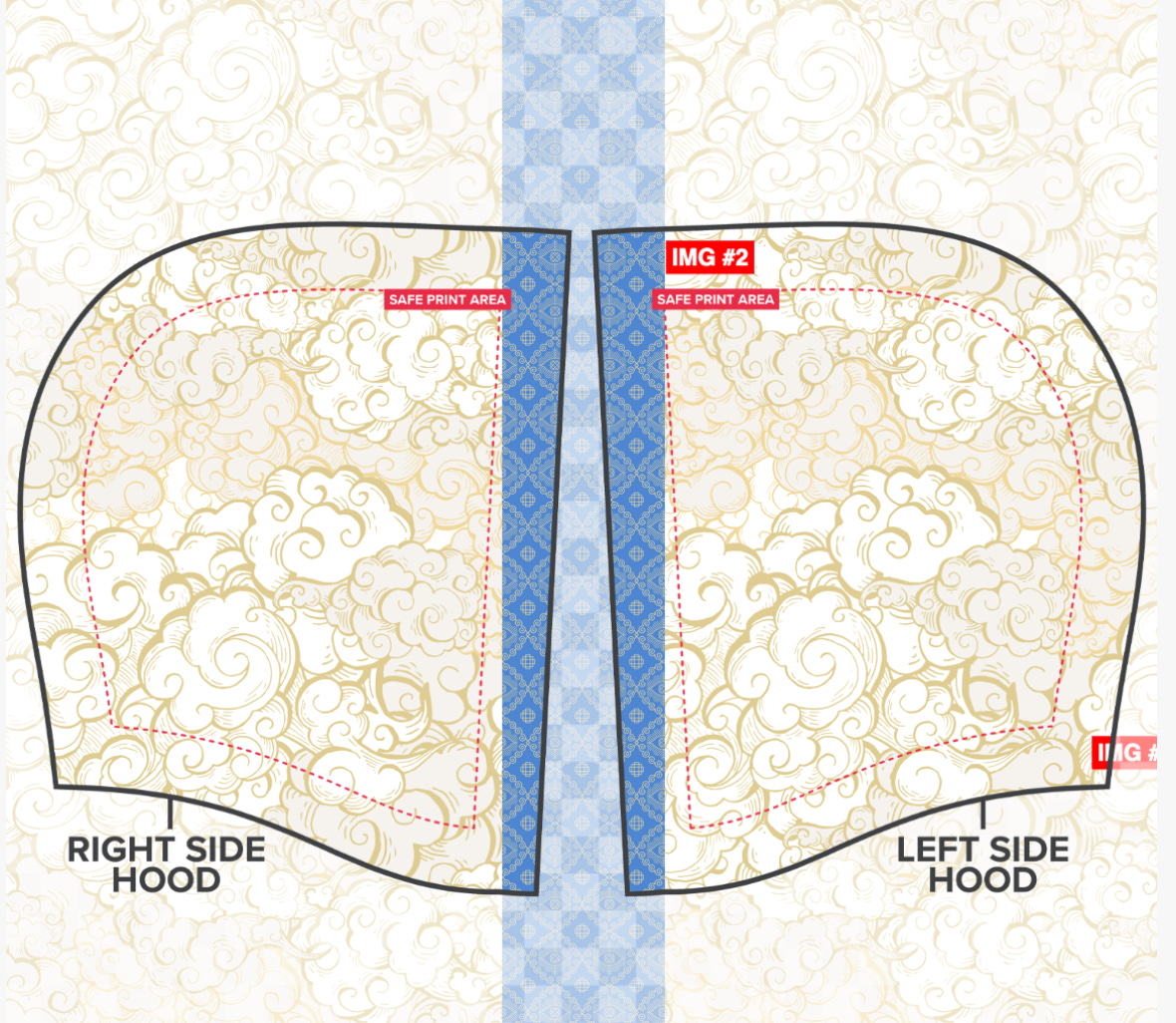

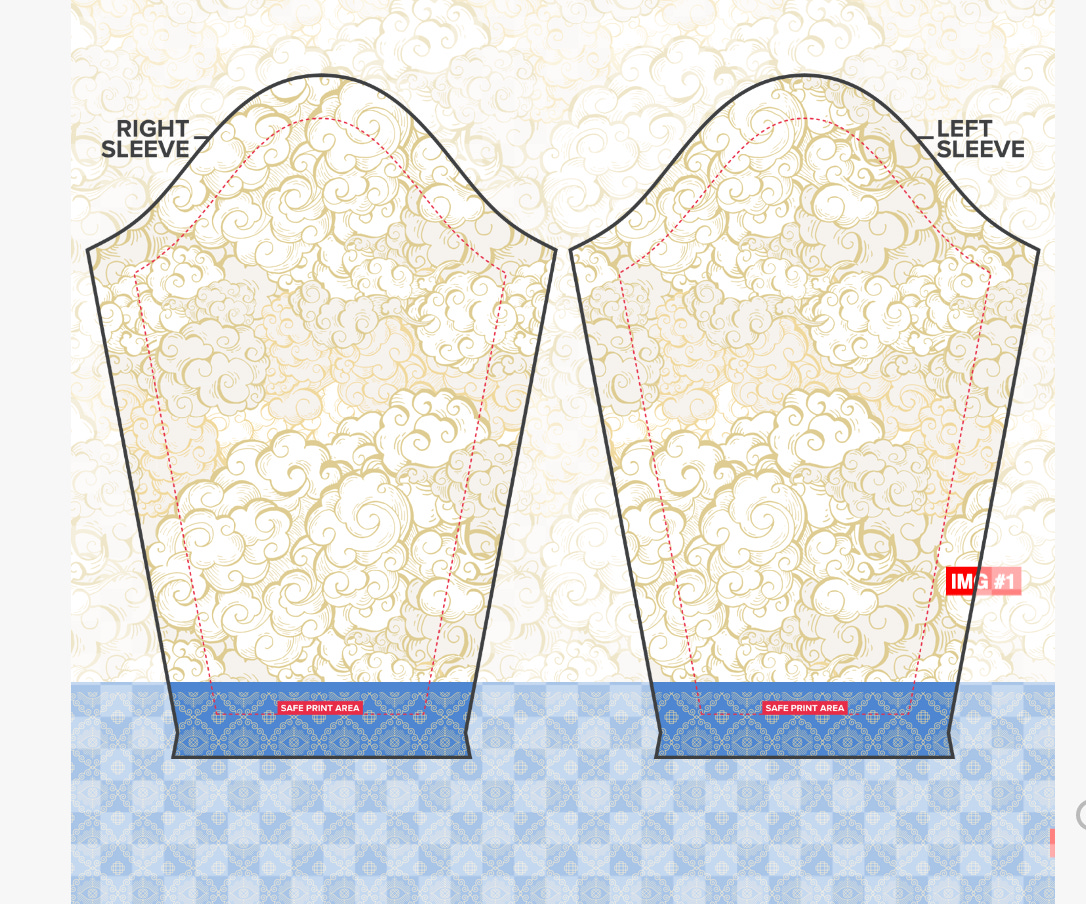

But, what about taking it to the next level? How about all over print designs that cover the entire garment?

Let’s rewind for a minute. A long time ago, I was a fan of Project Runway. Partly out of frustration of colors and patterns sold in mass market retail shops, I did some hobbyist attempts at making some simple coats, shirts, and dresses with pre-made patterns. Some turned out well, others were not so great. Along the way I realized how difficult and how much detailed labor goes into making clothes, and even the simplest T-shirt is not so simple when it comes to assembly. Even in 2023, some of the largest manufacturers still have a manual component to creating a t-shirt. Automation can help but there is a rigorous Q/C process, and if the sewing isn’t handled with precision, the entire garment goes into the trash.

While print on demand garments make it significantly easier for designers, the pattern choices are limited by the manufacturer. With online software tools, less time is spent on trying out physical print pieces and a lot of the ‘hit or miss’ guesswork from fabric store shopping is eliminated. There is less waste of fabric since all the ‘trials’ cost nothing to edit online. However there is a catch. On screen colors (RGB) look different from print colors (CMYK). In addition, samples must be ordered in order to validate the outcome of a design. What might appear crisp or transparent on screen might not print with the same quality in reality.

Print patterns also seem simple but are deceptive; something that might look good on at small scale might not look good when printed all over the garment. I’m not going to lie - expanding a collection from a few flat logo T-shirt designs to a full multi-part All over print design is actually quite difficult. What looks good in 2D flat on screen can actually end up looking terrible if its on a model in 3D, and not flow well. Clothing has movement whereas a 2D print image does not. Automated 3D generation of a model wearing the garment is helpful but moving from the 2D design to a 3D testing and visualization still requires a lot of repetitive editing.

In many ways the process of creating fashion and/or graphic design is very much like writing code. Its an editorial process that involves both form and function as well as style and end user consideration. At the end of the day we can agree that code has its function but it might not be pretty. And the same goes with fashion, its a functional piece of clothing that has utility but it might not be pretty and it might suit an individual tastes. Perhaps one could argue that Fashion is even more difficult than coding because you can’t please everyone. With code, as long as the code delivers what its supposed to do, nobody is going to sweat if you didn’t format the comments with a fine border detail!

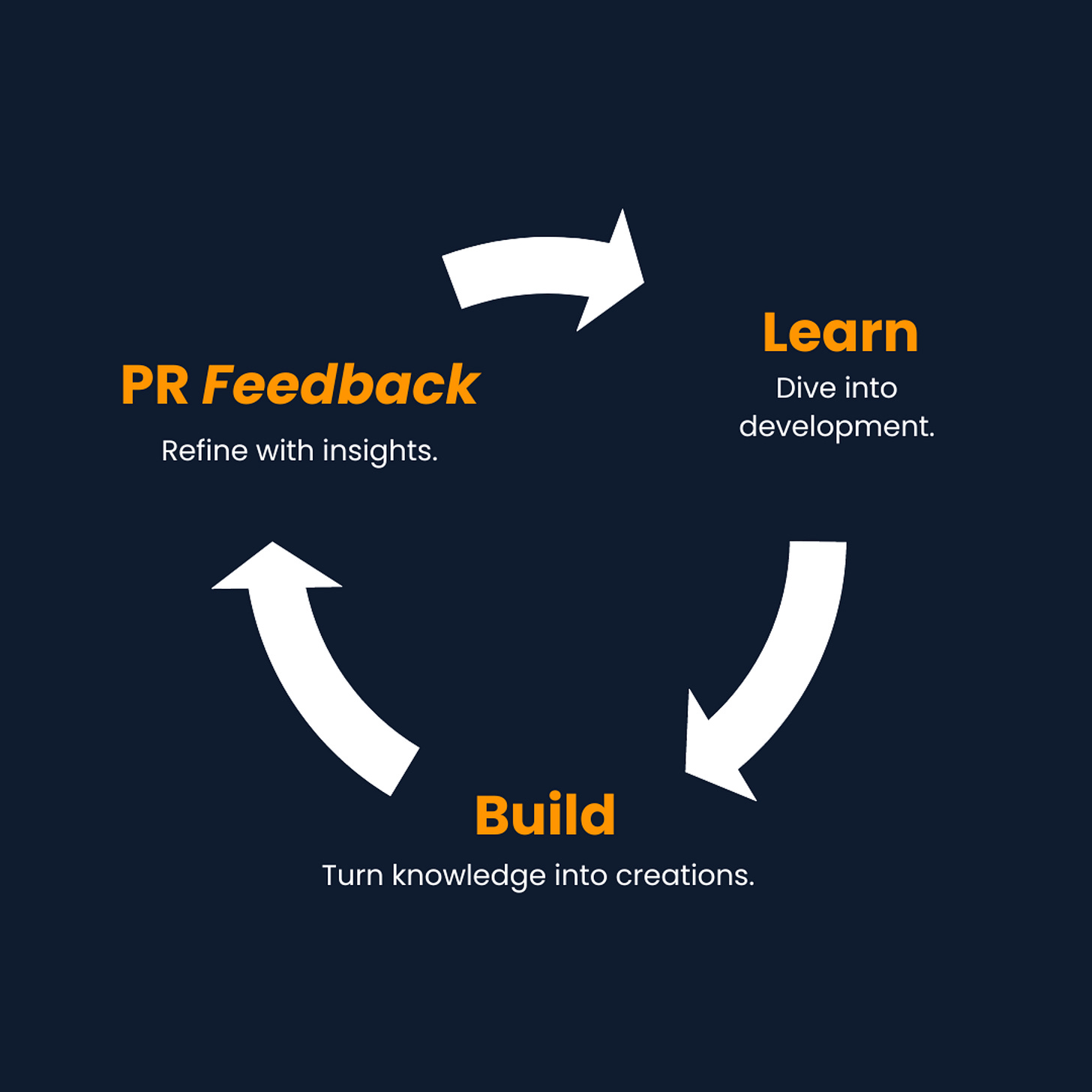

The Creative Process: Lather, Rinse and Repeat

The first time you do any creative process is the hardest. Then you repeat and it gets easier. Then after 100 to 1000 repetitions, not only is it faster, but the quality and progression is substantially better.

From writing code to writing a blog post to designing an all over complex print fashion outfit, the process is THE SAME.

Most importantly, feedback is critical. Early on, I asked for graphic design feedback. I actively sought out the most experienced designers, artists and anyone I knew who had an eye for fashion to critique even the simplest of T-shirt designs.

Why?

» Because critical feedback is key to growing faster.

The same goes with writing news articles. Anyone who has ever had experience working on a newspaper or a print publication knows the value that an editor-in-chief adds to their growth as a writer. Plus, short deadlines have a rapid growth mechanism automatically built in.

The News Cycle works like this →

Write the article → Get feedback from your editor → Rewrite and adjust accordingly to the feedback → Deliver the article to editor → Push to publication.

The Code Cycle for a project works like this →

Write the code → Submit the code as a Pull Request (PR) → Get a maintainer to review your code → Maintainer requests additional corrections → Edit your code and improve it based on the feedback from the maintainer → Maintainer approves and merges to the main codebase.

The Design Cycle for Print on Demand Fashion works like this →

Brainstorm up a Look → Create the design → Mockup your design → Show it to experienced designers for Review → Make updates and changes to improve → then publish the design for people to view and potentially purchase.

Lather, Rinse and Repeat!

The most important part I learned is not to dwell on a bad design for weeks and weeks. If its not working, drop it and move on. Work on something small and deliver it. Work your way gradually up to something more complicated. Mental Blocks happen, its part of the process - there’s writers block, designers block, coders block. Know when to step away and come back later. Banging your head against the wall is counter productive to making creative progress.

I'm not going to lie, it wasn't easy, but its nice to see virtual designs physically realized. I have so much more respect for the fashion industry than before. Its easy to take things for granted when you can just walk into a store and buy an item. To go through the entire process of designing and redesigning until an item is just right is incredibly difficult and challenging yet the insight and knowledge is invaluable!

Placement matters on 2D → 3D, and alignment precision is king. While not mandatory, knowing how garment construction works is helpful. Two piece construction, where the garment has an external shell and internal lining, is thicker than single piece and will have a different shape than single piece construction. The thickness may not match to the original design so adjustment may be needed. For example a thinner border design or a different pattern could be more appropriate.

The raw material that design is printed on, (for example micro-mink vs polyester vs cotton) has an impact on the final look and feel. Cotton tends to mute bright colors more, while polyester does not and the dye process also matters. For example, sublimation dye is very good, sharp quality and does not fade over time. All fleece garments in this article are printed using Sublimation dye with high resolution.

What is Sublimation is all about?

Sublimation (from Chemistry) is this fascinating process where a solid turns straight into a gas without even becoming a liquid. In the world of printing, it's the secret sauce behind those awesome designs on mugs, clothes, and various other items.

The Dye Sublimation printer - uses heat to sprinkle dye onto different materials. This printer gets the sublimation ink cartridges sizzling hot (around 350–400 ºF or 176–205 ºC) to transfer that vibrant dye onto the material. Find out more about the history of sublimation printing for fashion in this article.

So, how does Sublimation dye printing differ from Direct To Garment (DTG) screen printing?

Sublimation isn't just a surface process - the ink becomes one with the garment. What's unique about sublimation printing is its durability. No fading, peeling, or cracking. Prints will rock the same vibrant look years down the road. On the flip side, screen printing just sits on top. Sublimation loves polyester materials, while screen printing works best with natural fibers like cotton.

In case you were wondering, AI was not used to create the design work. Its not that I don’t like AI, in fact, AI was used for inspiration and some editing. I think AI is a good tool, but it doesn't allow for the precision work that's necessary, especially for specific detail at a specific place.

Perhaps there is a way to do specific, targeted placement of graphic designs to a flat clothing layout with AI but I haven't seen it just yet. Multi-layer editing tools in AI would be helpful, but they are still awkward and often miss the desired target. I am sure such tools will be available soon, with designers getting the ‘concept’ draft from the AI. They could refine AI drafts with precise positioning, sizing and styling with photoshop or illustrator tools.

Actual Product photos:

Each piece is a 2-piece construction, with the outer print shell dyed in a digital process then hand assembled and sewn with fleece lining on the interior.

Very warm and comfortable, perfect for winter time lounging or at an outdoor event. If you like these designs, you can get one here.

Browse the shop to see more Winter Fleece designs:

T-shirts and other small items:

https://lightning-games.printify.me/

Cheers.